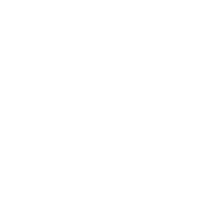

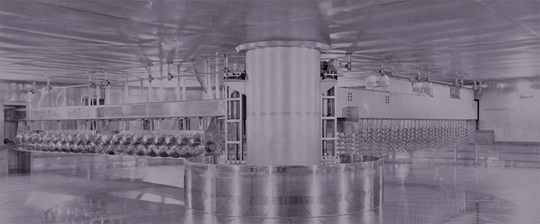

Disc Koji-Making System: It is a set of automatic cultivation system, which can realize automatic feeding, discharging, automatic turning, automatic temperature control, humidity control and automatic ventilation; it also will be dried and cooled after washing to ensure cleanness and sanitary; the equipment meets the production process requirements of brewing industry. ?

-

Automatic Disc Koji-Making System

Automatic Disc Koji-Making System

-

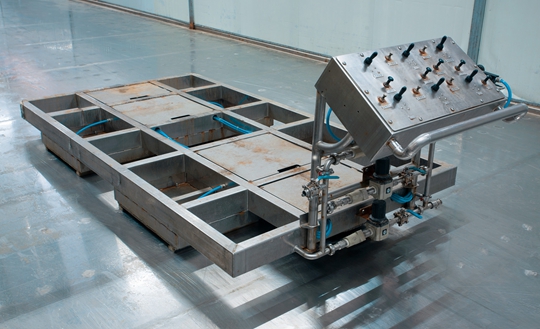

Seed Koji Cultivation Production Lin

Seed Koji Cultivation Production LinThe yeast culture production line consists of material mixing, material distribution, culture tray shelving (robot), automatic yeast culture, drying, yeast seed acquisition and tray cleaning.

-

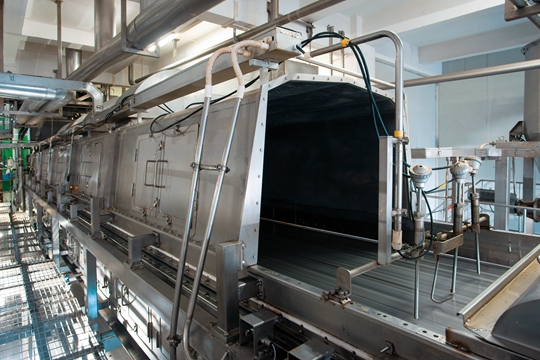

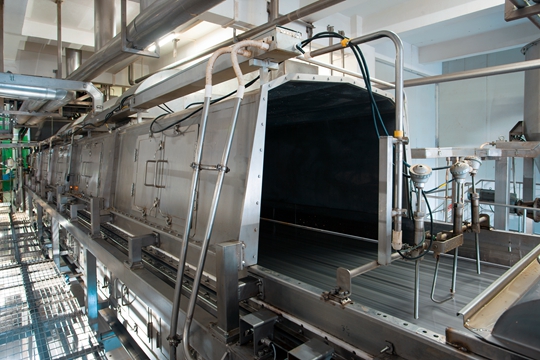

Continuous Cooking and Cooling Production Line

Continuous Cooking and Cooling Production LineThe continuous cooking and cooling production line system is suitable for the cooking of raw materials in soy sauce and brewing, wine brewing, fermented feed, biological engineering and other industries, so that it can achieve sterilization, gelatinization, softening, and ripening, and make proteins denature moderately, so as to meet the process requirements of koji-making...

-

Grain Roasting Production Line

Grain Roasting Production LineUse natural gas to heat the air, send it into the fluidized bed through a high-temperature fan, to contact the material evenly and fully, and roast it.

-

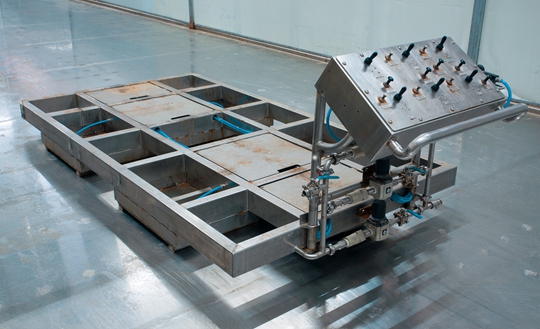

Continuous Squeezing Production Line System

Continuous Squeezing Production Line SystemContinuous squeezing production line is an equipment for separating solid and liquid, mainly used in soy sauce brewing, wine making, sugar making, chemical industry and other industries.

-

Screw Belt Mixed Conveyor

Screw Belt Mixed ConveyorThe screw belt mixed conveyor is composed of a U-shaped case, stirring conveyor belt, and transmission parts. It has a good effect on the mixing of viscous or cohesive powder and the mixing of liquid or paste materials in the powder and granules

-

Mixer Dispersion Machine

Mixer Dispersion MachineAfter adding auxiliary materials such as flour to the cooked material, it passes under the mixer through the conveyor belt, and the mixer rotates at a high speed to evenly mix and disperse the materials to improve ventilation.

-

Air Cushion Suspension Transportation System

Air Cushion Suspension Transportation SystemThe air cushion suspension transportation system uses gas film technology to lift heavy loads. When the air cushion suspension transportation system is in suspension equilibrium state, the friction between the entire system and the ground is basically zero. At this time, the system and load can be moved with very little thrust. It is widely used in the power industry, trains, automobiles, ships, airplanes, engineering machinery manufacturing, pharmaceutical industry, and food processing industry.

-

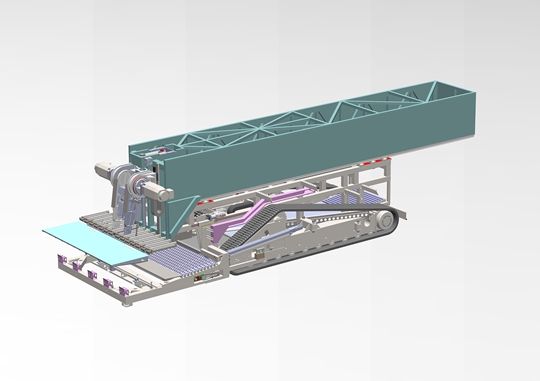

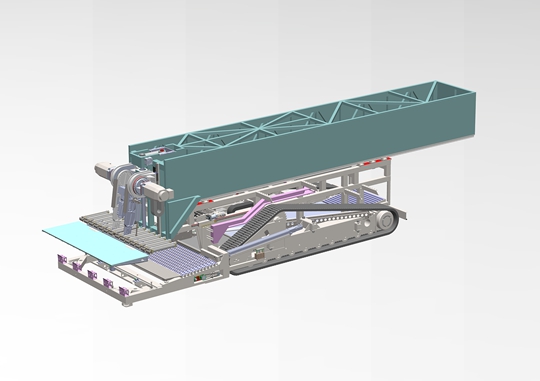

Intelligent Loading System

Intelligent Loading SystemIt belongs to the collective research direction of the logistics industry. Many well-known domestic enterprises have carried out the research and development of automatic loading logistics equipment. The products developed are still at the prototype stage and have not achieved large-scale production applications.

Automatic Disc Koji-Making System

Seed Koji Cultivation Production Lin

Continuous Cooking and Cooling Production Line

Grain Roasting Production Line

Continuous Squeezing Production Line System

Screw Belt Mixed Conveyor

Mixer Dispersion Machine

Air Cushion Suspension Transportation System

Intelligent Loading System