The continuous cooking and cooling production line system is suitable for the cooking of raw materials in soy sauce and brewing, wine brewing, fermented feed, biological engineering and other industries, so that it can achieve sterilization, gelatinization, softening, and ripening, and make proteins denature moderately, so as to meet the process requirements of koji-making.Combining the different requirements of different material production processes, Tianniang Company has developed continuous cooking lines suitable for defatted soybean cooking and round-off soybean cooking.

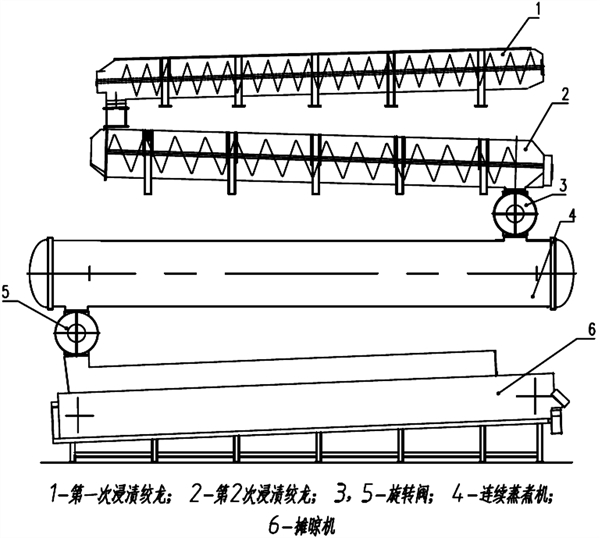

It is suitable for continuous cooking of smaller particle materials of round-off soybean; continuous production, controllable production pressure, temperature and speed.

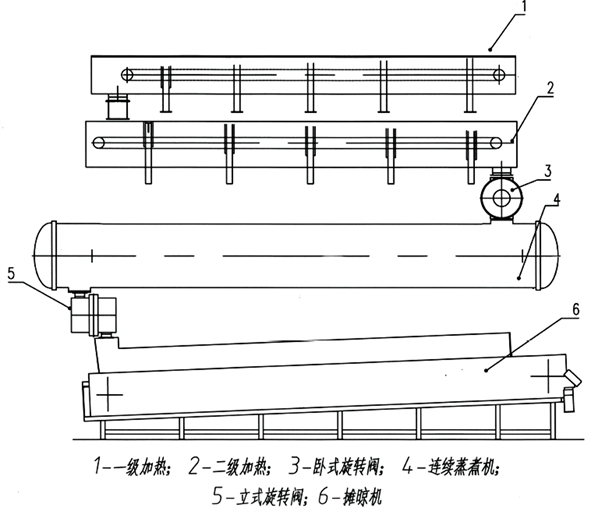

It is suitable for continuous cooking of smaller particle materials of defatted soybean; continuous production, controllable production pressure, temperature and speed.

Streamline continuous operation processes of moisturizing, preheating, high-pressure cooking, discharging, cooling, etc., which improves production efficiency, increases output, and reduces labor intensity.

Digital metering and control of feeding and water injection, precise control of cooking time, pressure and temperature, and adjust through the visual window according to the needs of different customers, and establish an execution menu which can be called at any time according to different materials and process requirements.

The raw materials are evenly moisturized, the cooking control is stable, the ripe material discharge is stable, the material is moderately denatured and the utilization rate of the raw materials is greatly improved, which is beneficial to the next process, the product quality is improved efficiently, and the economic benefits are improved directly.

The feeding and discharging rotary valves are made by special technology and have unique patented structural features, which can ensure the continuous operation of the entire production line, making it safe and reliable.

The cooling machine adopts stainless steel belt to convey materials. The steel belt has a scientific ventilation design, good cooling effect, and is equipped with an automatic deviation correction device. It runs continuously without deviation and has a long service life.

The production line incorporates Tianniang’s years of accumulated process experience in the industry, as well as years of management experience in the service industry, to realize unmanned production, intelligent fault diagnosis, maintenance output, equipment remote maintenance, and big data collection.

Model | Processing Capacity (T/h) | Maximum Cooking Pressure (Mpa) | Maximum Cooking Temperature (℃) | Material Cooling Temperature (℃) | Total Power (kW) |

| LZ-1 | 6 | 0.25 | 138 | 38 | 40 |

| LZ-1 | 10 | 0.25 | 138 | 38 | 50 |

Model | Processing Capacity (T/h) | Maximum Cooking Pressure (Mpa) |

| LZ-1 | 6 | 0.25 |

| LZ-1 | 10 | 0.25 |

Maximum Cooking Temperature (℃) | Material Cooling Temperature (℃) | Total Power (kW) |

| 138 | 38 | 40 |

| 138 | 38 | 50 |